- Home

- Products

- Paper Cup Machine

- JBZ-22D Middle Speed Paper Cup Forming Machine

JBZ-22D Middle Speed Paper Cup Forming Machine

JBZ-22D middle speed paper cup forming machine adopts the latest technology to make it energy-efficient, economical and durable. The shape is exquisite and the molds can be changed. SiNi will strive continuously to pursue the excellence in science and technology innovation. This paper cup forming machine adopts open cam design, automatic oil lubrication system and PLC control system to improve the machine function and performance.

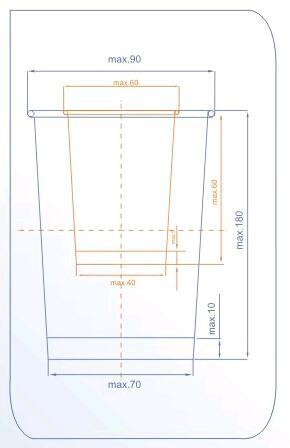

Min. and Max. Cup Size

Fine grinding machine body is very smooth, stabile and solid, insuring the stable running of the machine.

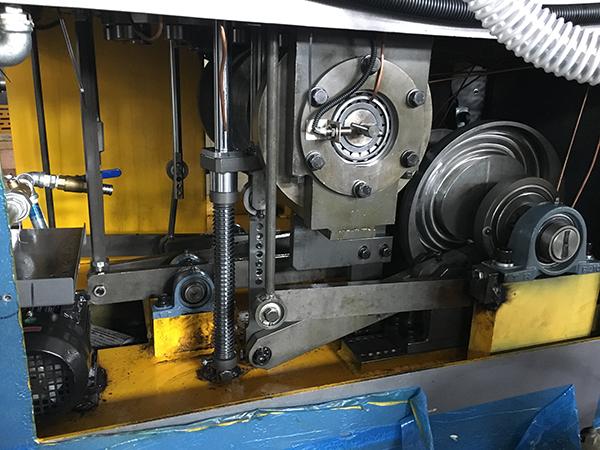

Open cam transmission system provides high precision and large output, improving the machine performance.

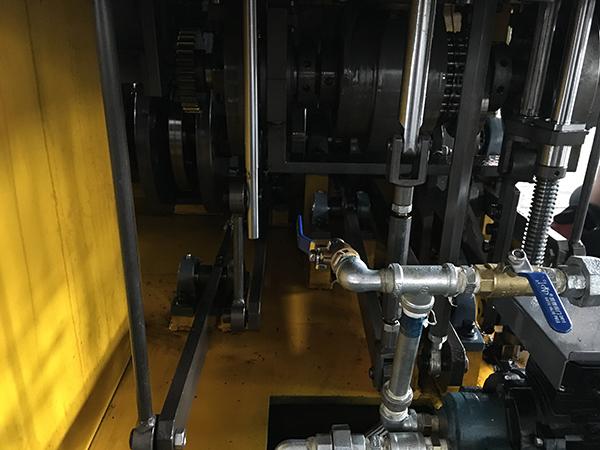

Automatic oil lubrication system is very easy to operate. The oil is very convenient to change. It makes your production easy and clean.

Every forming unit is very easy to operate and maintain.

Two Leister heaters are used for cup bottom sealing, highly increasing the heating effect and ensuring the good quality of knurling.

Unique welding head design ensures no vibration during the production.

Different from traditional iron mould, our machine uses aluminum alloy moulds. They are more durable, and don’t pollute cups.

Siemens brand PLC control system has good quality and excellent performance.

| Cup size | 6oz-22oz | |

| Top mouth diameter | 60mm-90mm | |

| Bottom diameter | 40mm-70mm | |

| Bottom depth | 5mm-10mm | |

| Height | 60mm-180mm | |

| Capacity | 6oz-9oz | 80-85pcs/min |

| 9oz-12oz | 75-80pcs/min | |

| 12oz-16oz | 70-75pcs/min | |

| 16oz-22oz | 60-70pcs/min | |

| Equipment size | Table-board | Complete machine |

| 1570mm×1100mm | 1880mm×1450mm×1900mm | |

| Power | 11.5kw | |

| Air consumption | 0.4m3/min | |

| Weight | 2200kg | |

| Work power | 6-6.5kw | |