- Home

- Products

- Paper Container Forming Machine

- JBZ-BJ Automatic Paper Meal Box Machine, Hamburger Box Machine

JBZ-BJ Automatic Paper Meal Box Machine, Hamburger Box Machine

It is an ideal equipment to produce paper box such like hamburger box, chips box. Fried chicken box, kids meal box, etc. with firm structure, high quality, low noise and high efficiency. It has paper feeding unit, adjusted unit, glue unit, forming unit, Making Products collecting unit and also counting unit.

Machine detailsWork principle:

The feeder transmits the pre-printed and cut cardboard from the paper shelf to the convey chain and the sends it to the shaping mold, during the procedure, the cardboard has been glued an you can adjust the position of the gluing, the volume of gluing can be measured while in progress with our stopping word. After being glued, the cardboard will be conveyed to be shaped and collected to be auto calculated as the preconcert quantity and auto mark without stopping production, structure: Control unit, paper feeding unit, paper transfer unit, glue spreading unit, forming unit, collecting unit.

Key parts(sell points )

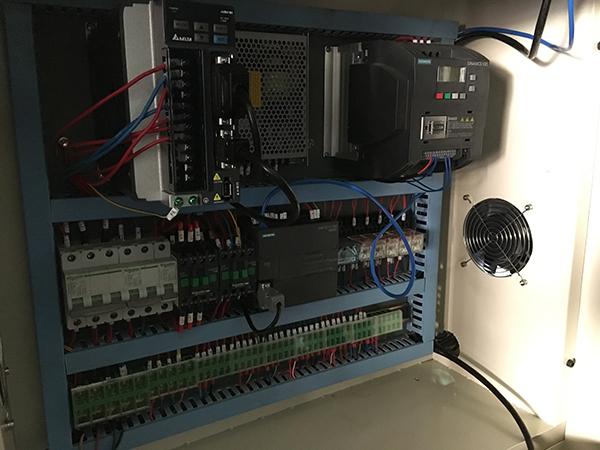

1).Electrical components we use international famous brands such as Japan Omron, French Schneider, Germany Siemens, delta etc import parts. And we use PLC programmable control and touch screen interface

2). Device for feeding Water-based adhesive (glue)

High efficiency and high precision to feeding glue and the sealing edge of the carton can be adjustable, its device design reasonable , compact form and running steadily ,easy and convenience to clean

3). Finished carton outing device

Full automatic carton outing device (feeding, collection, stacking) and fixing with counting, convenient for packing and save labors

4).Photoelectric failure-detecting system is available, if there is no papers or paper feeding blocking , the machine will stop automatically by itself, so, it can reduce the cost consume ,and increase more safety performance

| Produce speed | 60-160pcs/min (different paper box shapes, the speed is different ) |

| Raw material | 200-600gsm card board /ivory paper/ corrugated paper thickness :1.5mm |

| Carton size | Box length: L 100-450mm and angle: 5° -40° Box width :B 100-580mm Edge height H 15-200m |

| Packing size | 3600x1400x1700 mm |

| Total power | 380v,50hz, 4.5kw |