- Home

- Products

- Plastic Thermoforming Machine

- JBZ-420W Automatic Plastic Thermoforming Machine

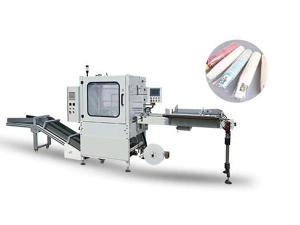

JBZ-420W Automatic Plastic Thermoforming Machine

Main features:

1. The achievement of GMP/QS double standard purification clean production, improve product hygiene and safety,

2. Unwinding, forming, punching, stamping five stations synchronization production, robot gripper feed, compact structure.

3. The use of special feeding devices, electricity savings of 20 times, special stamping device, material savings one of fifth

4. Travel adjustable, mould replacement is simple and can easily replace size, applicable to a wide range of production

5. Adopt PLC man-machine interface, frequency conversion stepless speed control, PC Circuit Control Panel

6. Design the modules according to customer requirements

Main functions:

HIPS PVC PET PS material

| Cutting Frequency | 15--45(times/min) |

| Power | 380v/220v/50HZ |

| Stroke adjustable range | 160mm |

| Max. Forming Depth | 45mm |

| Max. Forming Area | 420×160mm |

| Motor Power | 4kw |

| Consumption | >0.2m3/min |

| Pressure | 0.4--0.7mpa |

| Overall Dimensions | 2500×1000×1600mm |

| Weight | 1200kg |

Option for Customers:

Add outer cover as below(extra to pay)