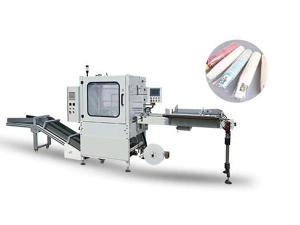

Flexo Printing Machine

Work principle

1. Adopt ceramic ink roller to feed ink.

2. The material discharging and receiving are controlled by carbon powder brake and clutch (Mitsubishi automatic tension controller is optional).

3. All printing units adopt 360-degree circumference register adjustment.

4. All printing units are provided with a set of infrared drying unit.

5. The ink roller automatically breaks away and rotates at low speed when the machine stops to prevent the ink from turning dry and hard.

6. The main motor adopts imported frequency conversion step-less speed regulating.

7. The machine finishes the steps from the paper supply of drum feeder, deviation rectifying, printing and automatic infrared drying to winding, being the most ideal machine type for printing paper cups for printing plants.

| Machine Type | HSR620 | HSR850 |

| Printing Speed | 50m/min | 50m/min |

| Printable Colors | 2-6 Colors | 2-6 Colours |

| Maximum Width of Roll Paper | 630mm | 860mm |

| Maximum Width of Printing | 620mm | 850mm |

| Maximum Diameter of Unreeling | 1,400mm | 800mm |

| Maximum Diameter of Winding | 1,400mm | 800mm |

| Printing Girth | 180-420mm | 180-420mm |

| Registering Precision | ±0.15mm | ±0.15mm |

| Power source | 380V, 50HZ | 380V, 50HZ |

| Power consumption | 22KW | 24KW |

| Main machine packing size | 5,000*1,500*2,500mm | 5,000*2,000*2,500mm |

| Machine Weight | 4500KG | 5,000kg |